Product & Services

Our involvement starts in the early stages of our projects, in the Design and Value Engineering stages, as we offer our acquired knowledge on the value implications of design decisions, material availability and process optimization of steel structures. Further on, the strict attainment of our customers’ requirements and schedules is ensured throughout the entire value chain, whether it’s through our internationally compliable fabrication processes, or through the precise project planning and site installation. As the integrated structural steel solution provider for the region, our diverse range of products is permanently being adapted (remove “to tailor-made packages”), covering all areas of steel fabrication:

- 1. Heavy built-up assemblies,

- 2. Hot Rolled steel structures,

- 3. Secondary steel (platforms and walkways),

- 4. Miscellaneous works (handrails and ladders),

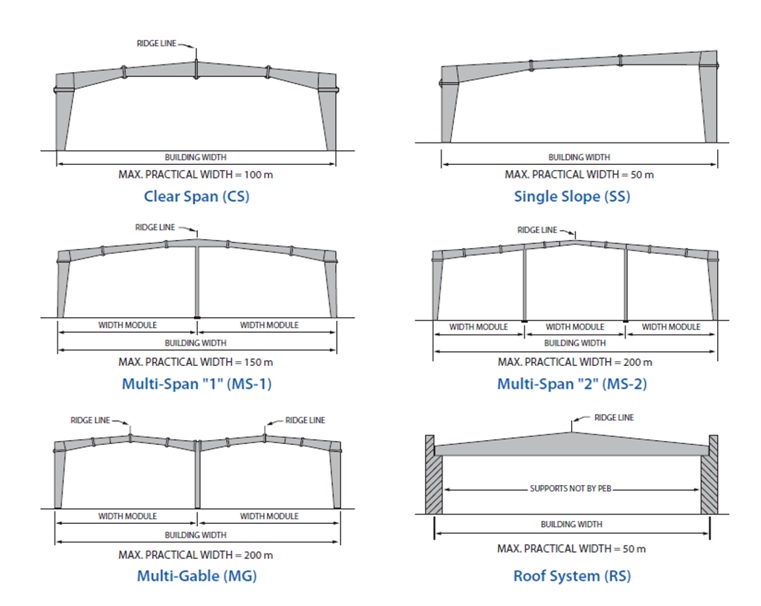

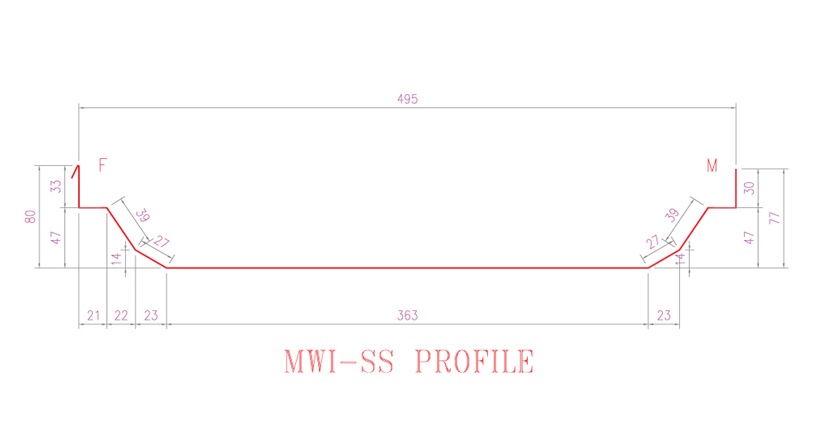

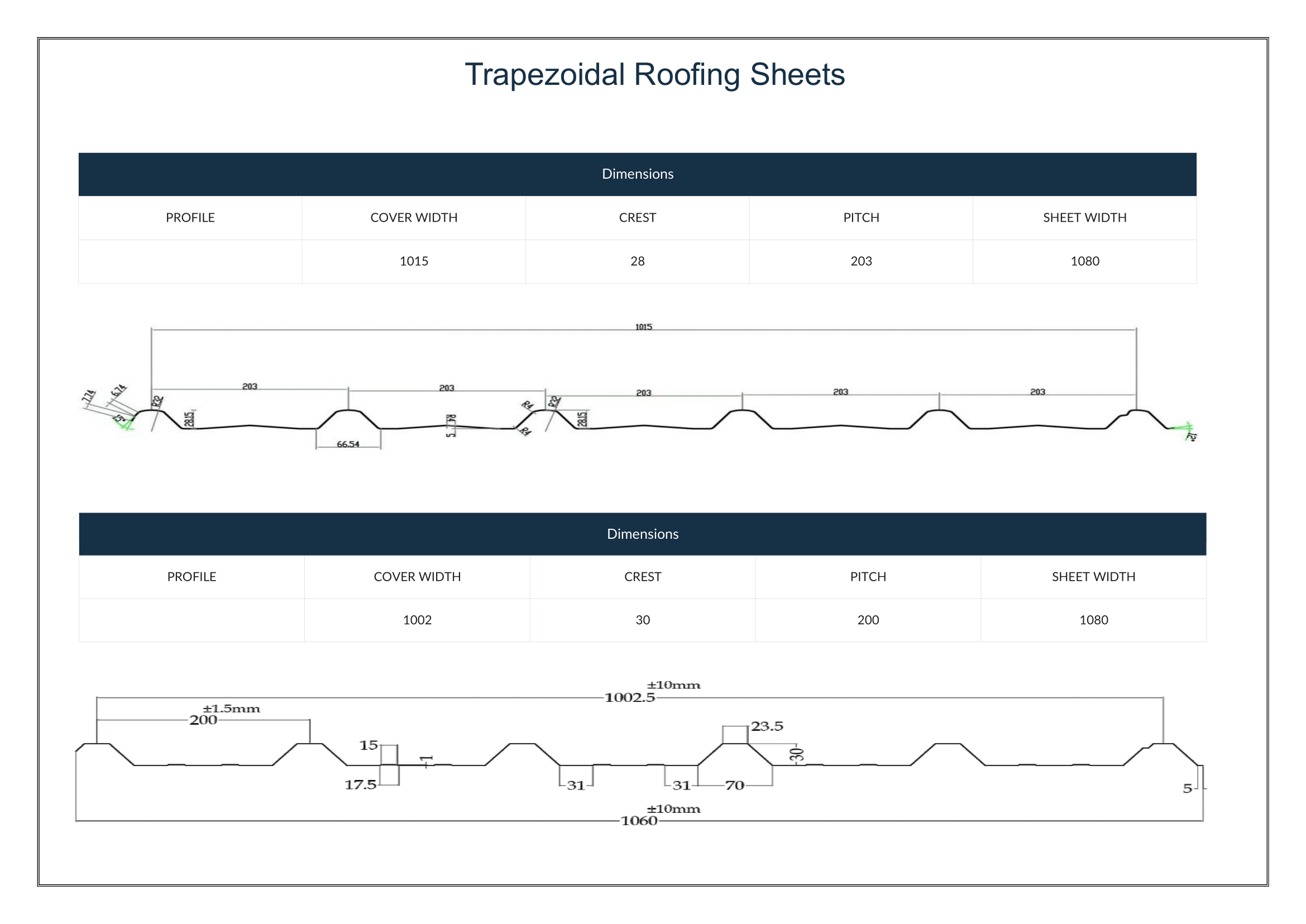

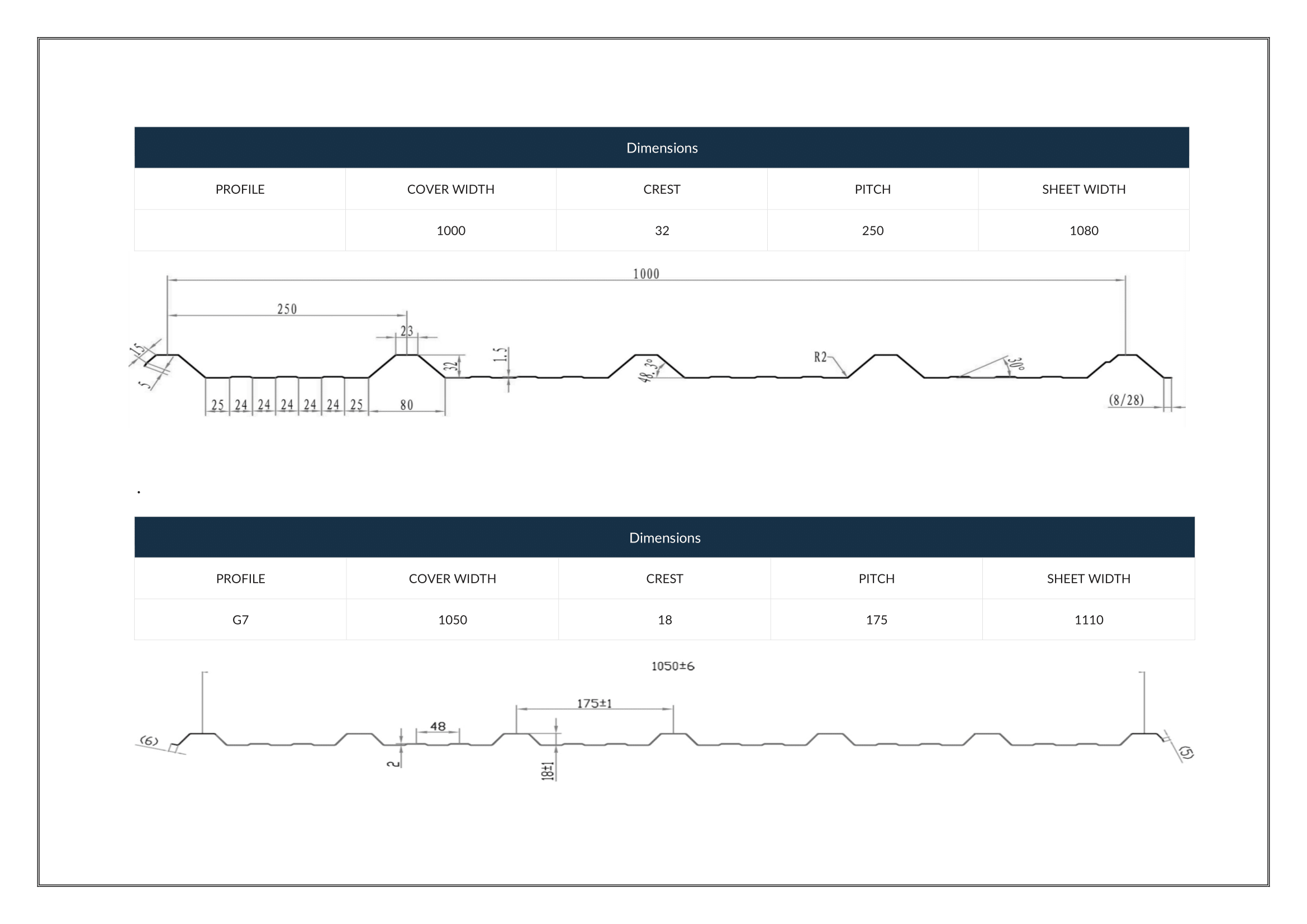

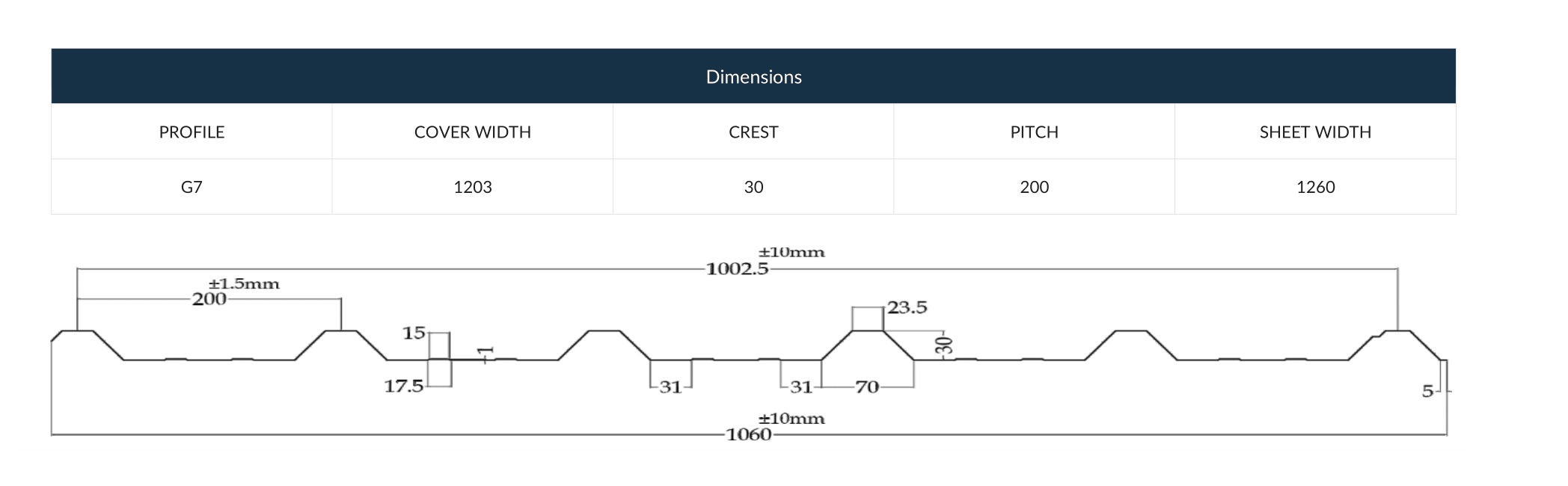

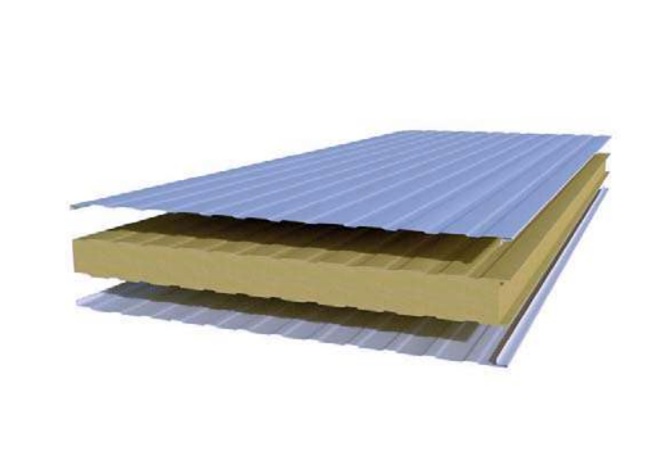

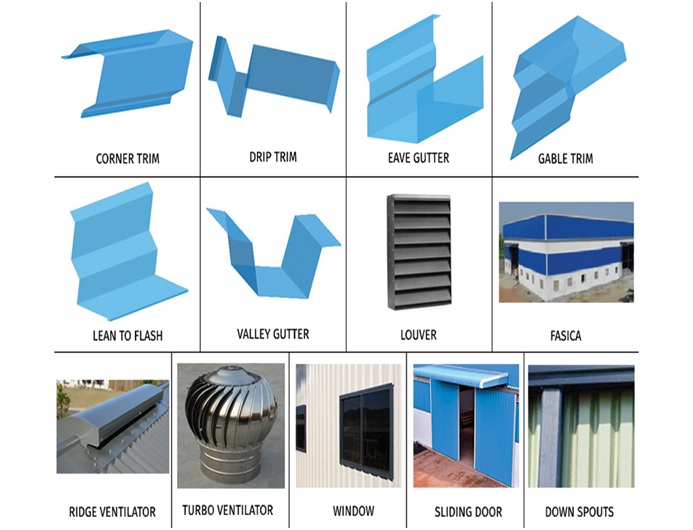

- 5. Roof & wall panels

Moreover, we relieve our clients from the pressure of managing several contractors concurrently with our acquired know-how and our well-established international partner network base, while ensuring the successful subcontracting of a wide range of operations and services Working for both governmental and private sectors, we have the financial and operational capabilities to operate several projects concurrently, while ensuring all our customers’ demands are surpassed. Whether it’s a complex project with comprehensive legal compliance specifications or a smaller project which would gain from the advantages of bulk material orders, we provide the competitive rates and quality-proven systems that will enhance the value our customers’ projects